NASA To Build 3D Printed Cameras and Optics

By using 3D printing, the cameras can be made more simply, and with precise designs that would otherwise be impossible

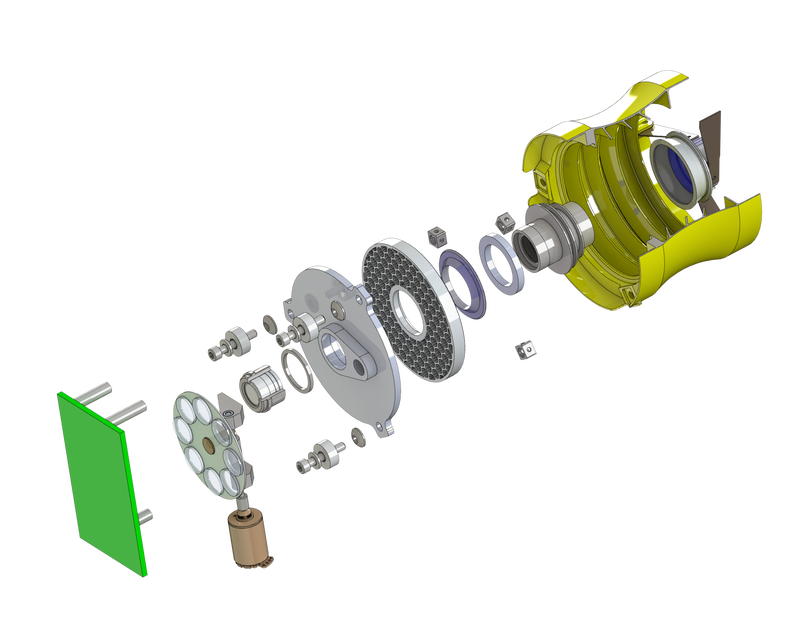

If you’ve ever seen a disassembled camera or lens, you know that they’re made of an incredibly complex set of interlocking pieces, each of which must be manufactured to precise specifications. But what if, rather than needing to assemble dozens of individual components, you were able to 3D print an entire structure, saving on the number of pieces needed, but also allowing for designs that might not otherwise be possible? That’s exactly what NASA’s Jason Budinoff is working on at the Goddard Space Flight Center in Greenbelt, Maryland.

Budinoff is set to complete a 50mm camera, whose “outer tube, baffles and optical mounts are all printed as a single structure”. Designed for use on a tiny satellite, Budinoff is also working a 350-millimeter (14-inch) dual-channel telescope, again using a 3D printed structure.

These test models that Budinoff is working on could provide immense benefits for not just simplifying the construction of optical structures, but also in terms of cost. A 3D printed structure can take the place of 5-10 times the number of parts of one that’s traditionally assembled, and in this case, the baffling that’s used to reduce stray light can be printed in a way that can’t be created with traditional manufacture. As NASA describes it:

Using 3D printed components means less time, lower costs, and simpler construction—all of which is a major boon for getting the hardware that they need, faster and cheaper.

While custom 3D printed components are probably a long way from replacing traditional cast or milled pieces for high-run productions of optical gear, for instances like this where you need only a small number of very precisely designed pieces, it’ makes an awful lot of sense.